Made with the world’s only renewable building material.

Approximately 85% of greenhouse gas (GHG) emissions related to building construction and operations are associated with building materials. Of GHG emissions from building materials, 95% are related to concrete and steel. By substituting wood for concrete, Assembly reduces embodied emissions by 40%.

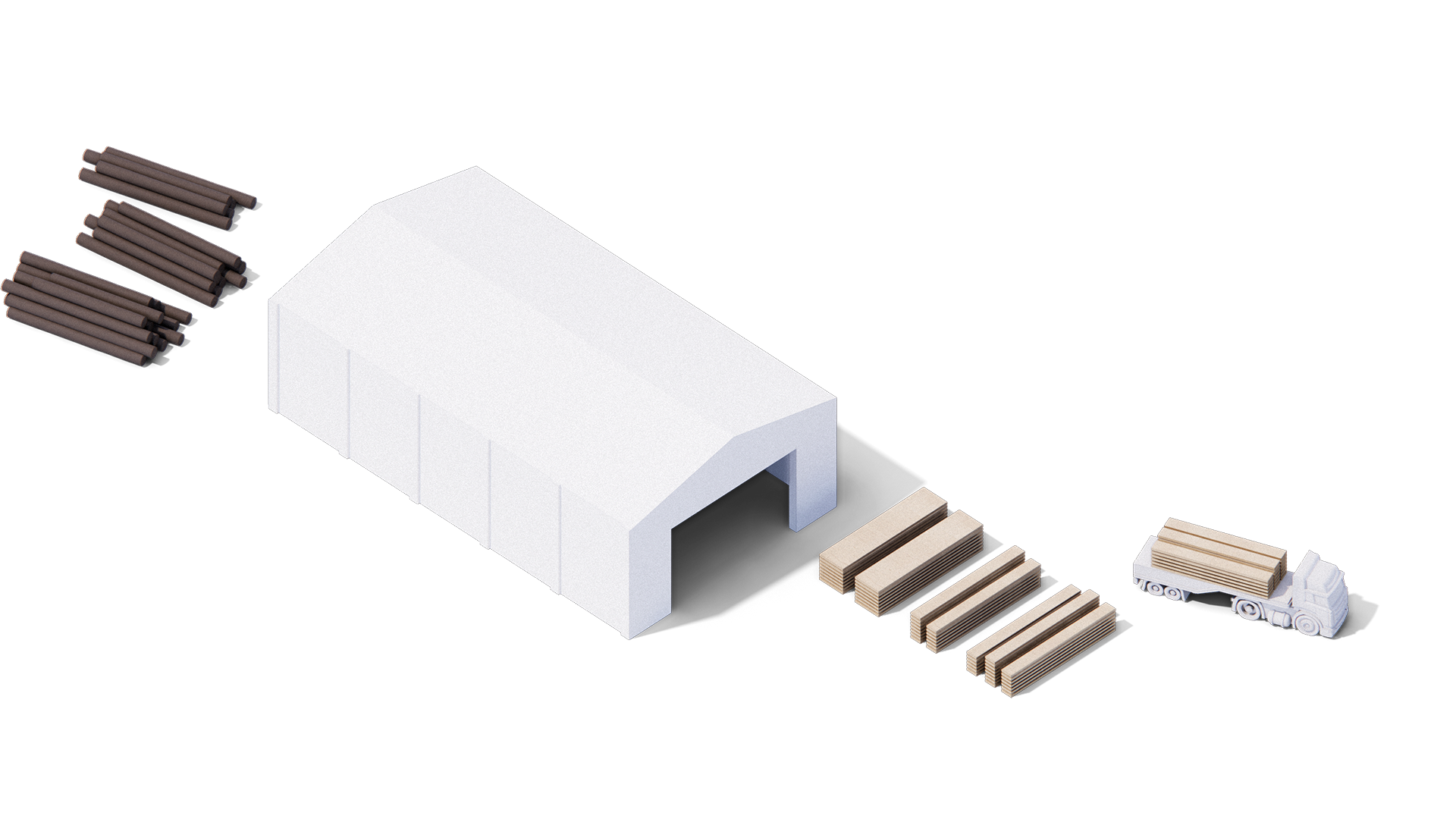

1

Assembly builds with wood grown and harvested in Canada.

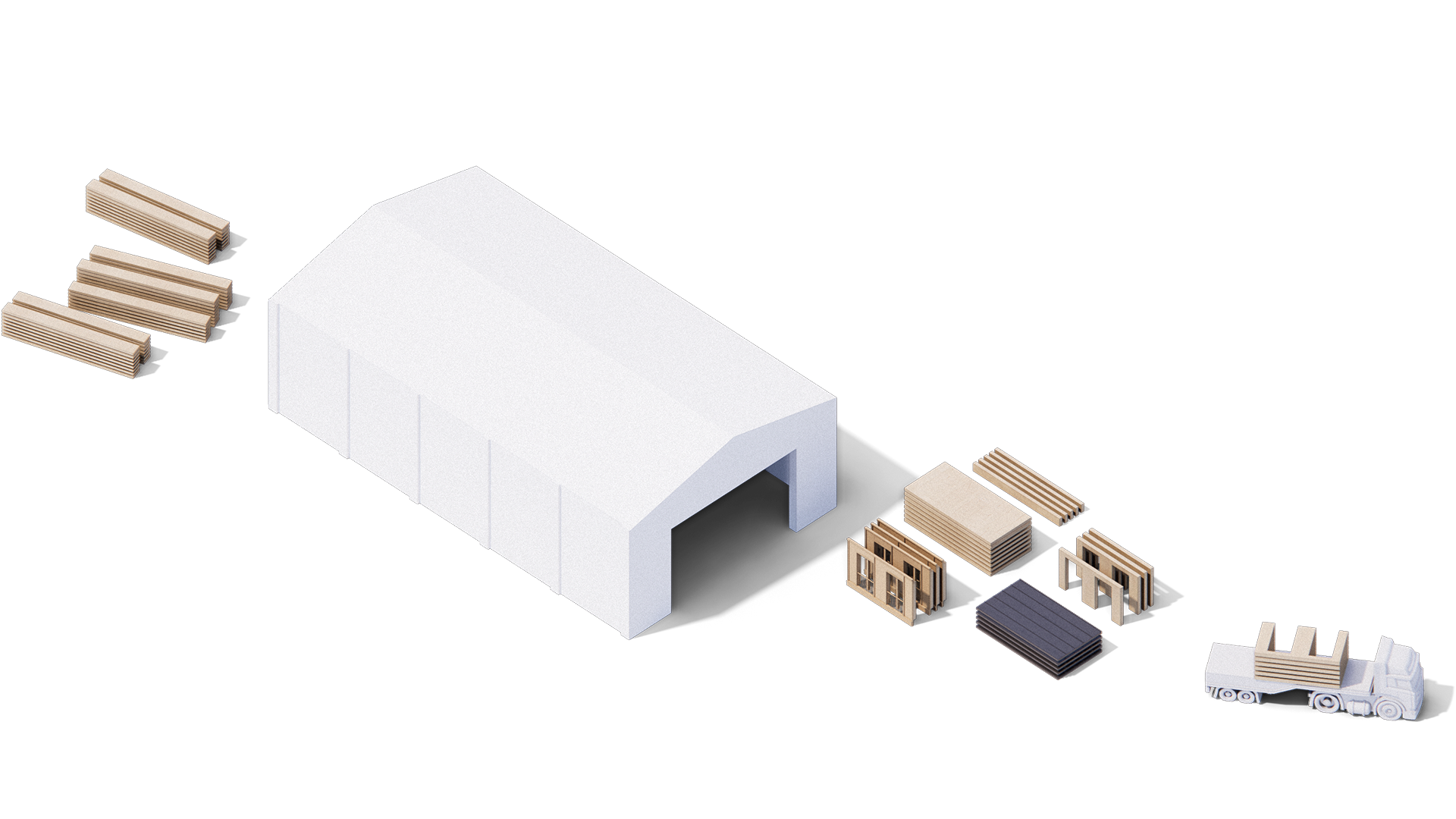

2

Our raw material is processed in Canada into building components.

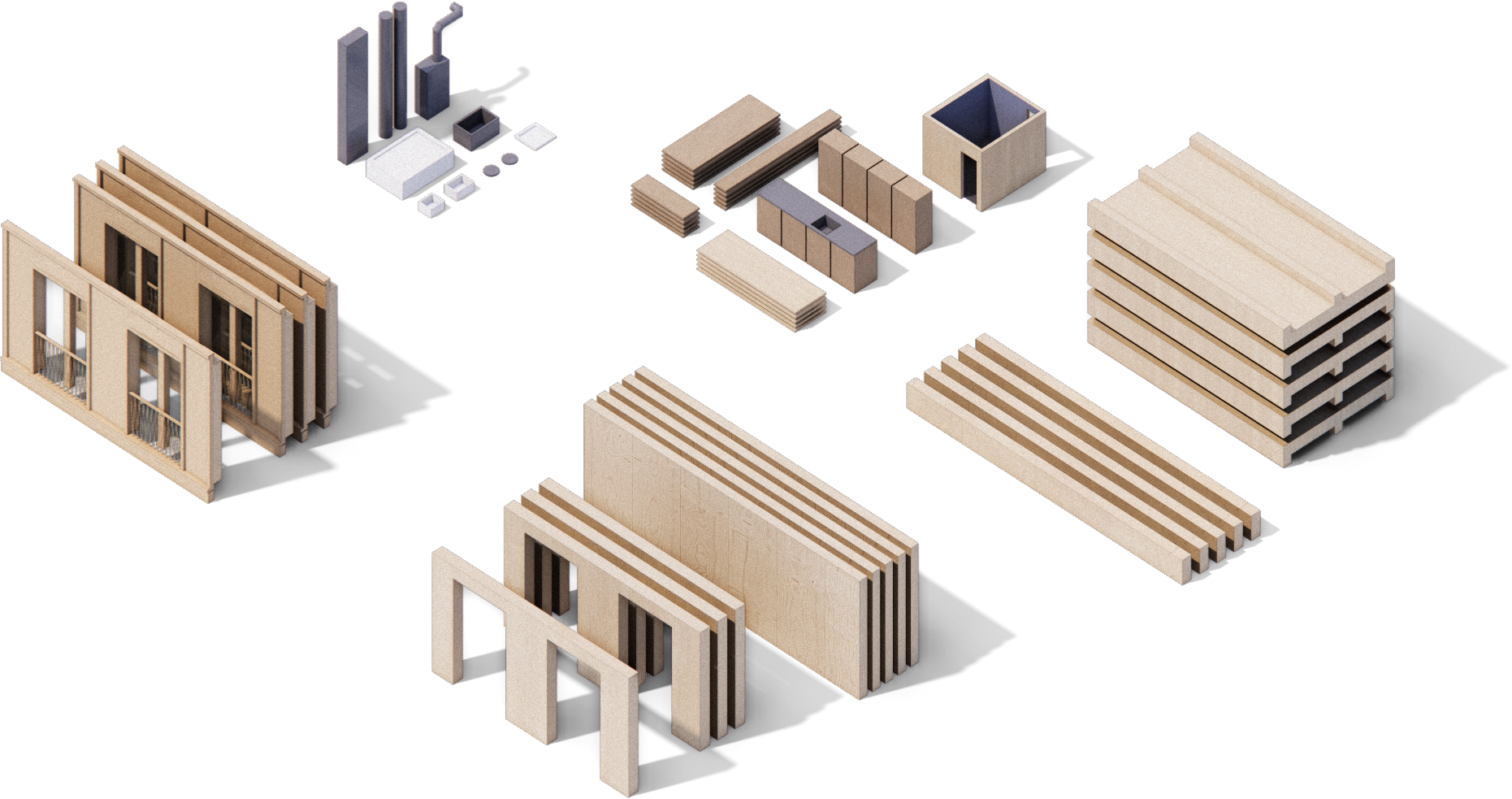

3

4

Our repeatable kit-of-parts consists of 5 basic components: decks and beams, load-bearing walls, facades, interior finishings, and technical installations.

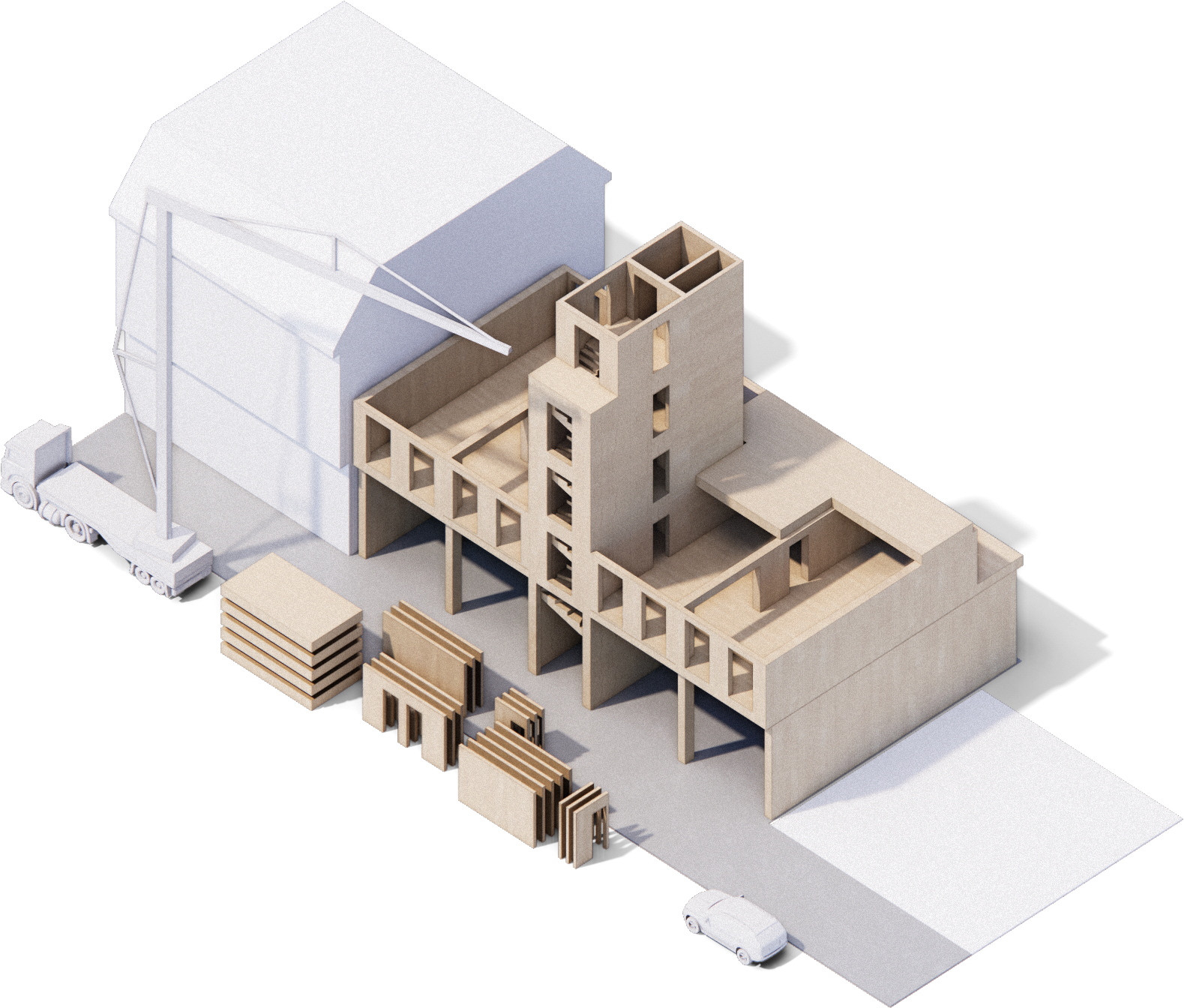

5

Prefabricating materials means construction requires less space, less time, less disturbance.

6

Assembly thermal ratings exceed building code requirements for energy efficiency reducing GHG emissions and utility costs.

Reduced embodied emissions and maximized construction efficiency at every stage.

Integrated Project Delivery and parametric modeling allows us to create a digital twin of the building, uncovering inefficiencies in the pre-construction phase as opposed to onsite. Onsite material waste is reduced by 80% and on-site labour is reduced by 50%.

Assembly maximizes efficiency and livability through highly intentional design that prioritizes beautiful, functional spaces that lower our carbon footprint. Compared to typical buildings, Assembly’s unique designs reduce superfluous floor area and the associated embodied and operational GHG emissions.

Air handling in Assembly buildings uses a natural passive approach supplemented with enhanced fresh air, ventilation, and exchange filtration handling systems. We do not use gas, opting for geothermal when applicable.