We’ve got this.

Assembly offers end-to-end service from

project feasibility to time of occupancy.

Site Assessment

The process begins with a site evaluation to identify the building product most suitable for the site.

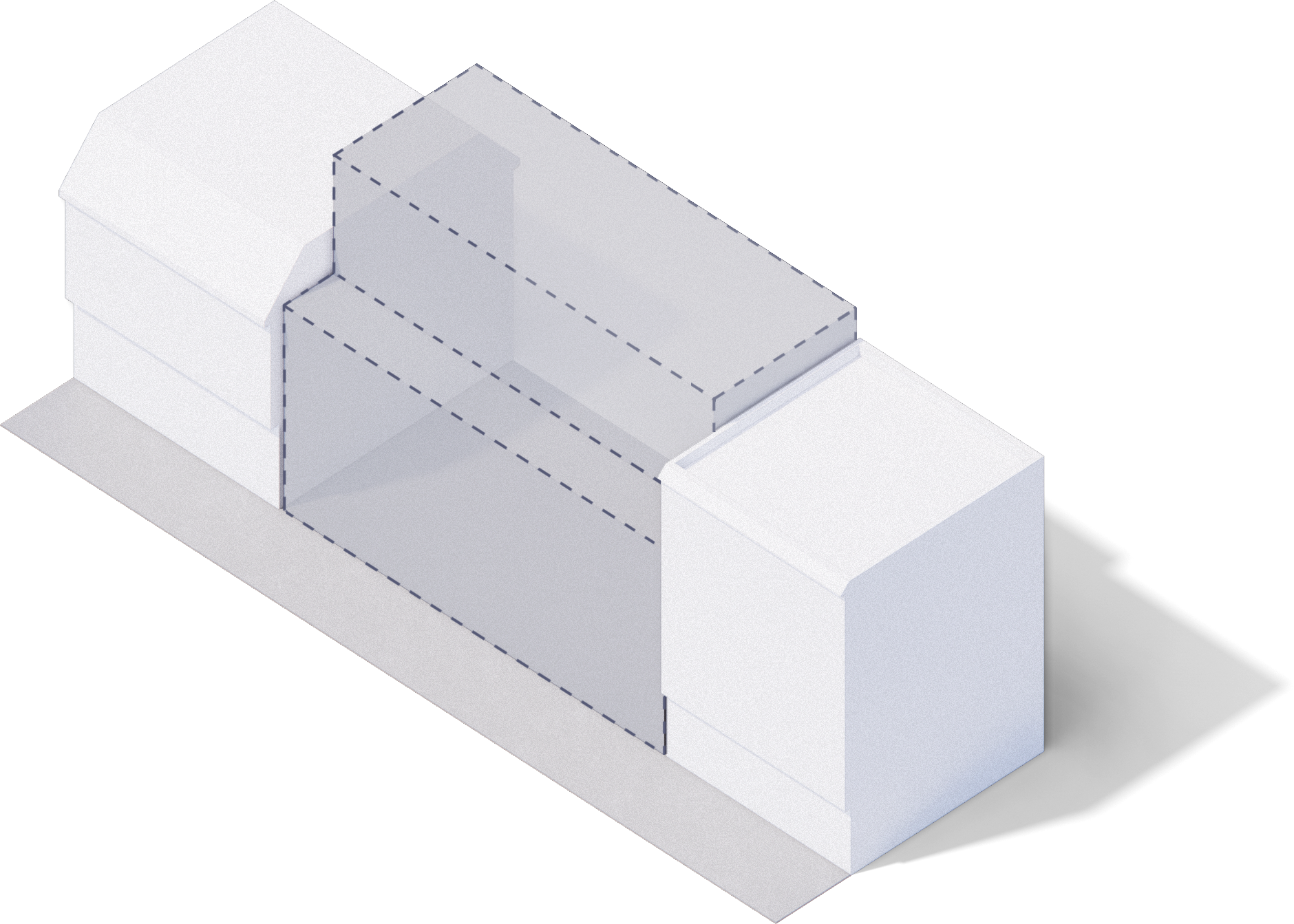

Design Adaptation

Building Information Modelling (BIM), and other parametric design software, enables our team to collaboratively configure and design our buildings. Assembly's digitally designed assets include

bathroom and kitchen pods, floor cassettes, wall and ceiling panels, facades with cladding, and panel assemblies. These repeatable building components are configured to meet the project's unique needs and enable customizable finishings and facades. Parametric modeling allows us to see and test the end product, make site-specific changes and test project proformas at the same time—reducing our design timeline by 60%.

Entitlements

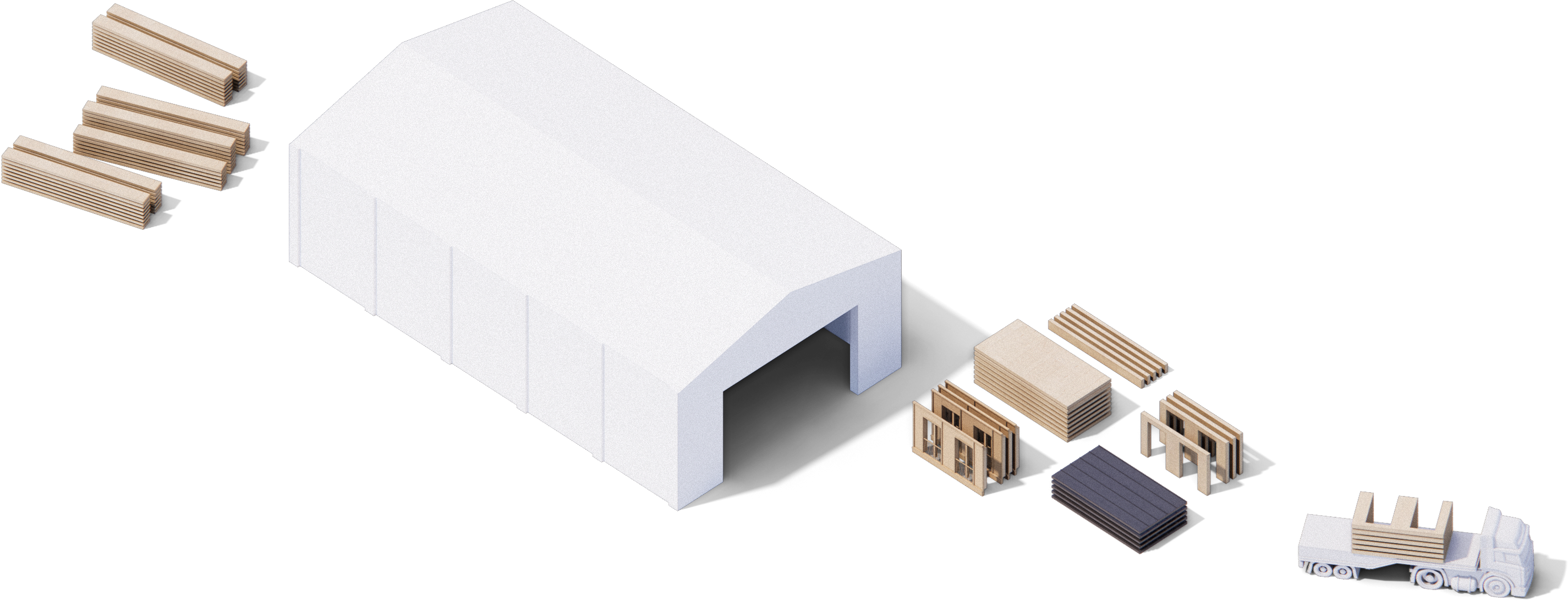

Manufacturing

Assembly building components are manufactured offsite at our partner Fab Structure’s factory in Ripon, Quebec and delivered just-in-time to the project site. Manufacturing offsite circumvents labour shortages and shortens onsite construction time and it results in a higher quality building at a lower cost.

Construction

Onsite construction takes months as opposed to years with custom builds. Assembly builds from the lane, which enables us to avoid street closures for the duration of the project. Just-in-time delivery and logistics management allows Assembly to meet the challenging needs of small urban-infill lots, which is why we can succeed on projects other builders can’t.

Turnkey Delivery

The completed building is ready to be furnished at the time of hand-over. Assembly will handle warranty and closeout. Assembly will handover the building to the operator to manage maintenance and operation at completion. They will be available for any warranty issues post completion.